Transforming Waste Into Wonder: How BASF Is Pioneering Sustainable Future Through Innovation

share

Summary:

BASF’s participation in K 2019 demonstrated how innovation and sustainability can intersect to create immersive experiences. Through its ChemCycling project, BASF transforms hard-to-recycle plastics into high-quality raw materials, advancing the circular economy. Collaborations with companies like Pyrum Innovations, Henkel, Schneider Electric, Quantafuel, and REMONDIS further strengthen these efforts. Highlights included the VisionVenture sustainable camper van, showcasing BASF’s advanced materials in mobility, energy efficiency, and design. Experiential agency Sentient By Elysian enhanced these innovations with immersive showcases, such as the Escape Room for sustainability education and the Peek-A-Boo platform for dynamic automotive reveals. Together, BASF and Sentient By Elysian illustrate how technology, design, and sustainability can create impactful, engaging experiences for audiences worldwide.

Table of Contents:

BASF’s Crucial ChemCycling Project at K 2019

Sustainability Meets Innovation

VisionVenture: Powered by BASF's Cutting-Edge Technology

Create Futuristic Automotive Reveals with Cutting-Edge Technology

"The greatest threat to our planet is the belief that someone else will save it," said Robert Swan, the first person to walk to both the North and South Poles and a lifelong advocate for sustainability. His powerful words emphasize the urgency of collective action in addressing the escalating plastic waste crisis—one that demands the commitment of individuals, businesses, and innovators alike.

Around the globe, creative minds are uniting to combat the growing challenge of plastic waste. Companies are adopting sustainable practices, communities are embracing eco-friendly behaviors, and entrepreneurs are developing transformative technologies that turn waste into valuable resources.

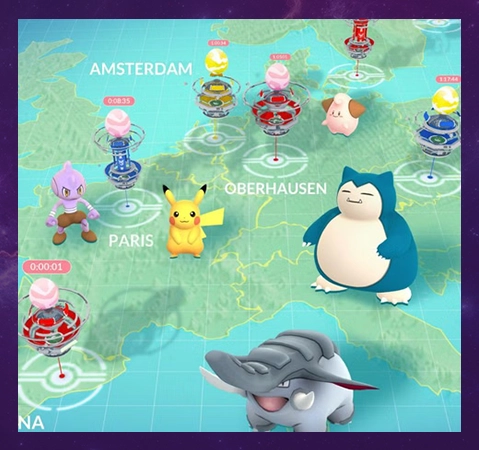

A pivotal moment in the fight against plastic waste came at K 2019, the world’s largest trade fair for plastics and rubber, held in Düsseldorf, Germany. The event brought together industry leaders to showcase the latest innovations in reducing plastic waste, improving resource efficiency, and advancing the circular economy. One of the standout contributors at the fair was BASF, a global leader in chemical innovation, which unveiled its ChemCycling project. This groundbreaking chemical recycling technology converts even non-recyclable plastics into high-quality, reusable materials. By applying advanced chemical processes, BASF is helping to close the loop on plastic waste, transforming it into valuable raw materials for new products.

BASF’s work at K 2019 is a testament to how businesses can lead the charge in creating a sustainable future. Their innovative approach demonstrates the potential of collaboration and cutting-edge solutions in addressing the global plastic waste crisis. As Robert Swan's words remind us, the responsibility to protect our planet lies with all of us—and events like K 2019 serve as a powerful reminder of the impact we can have when we come together for meaningful change.

BASF’s ChemCycling Project: Leading the Charge in Plastic Recycling at K 2019

At K 2019, BASF introduced its pioneering ChemCycling technology, a transformative approach to chemical recycling that turns plastic waste into valuable raw materials. Using advanced processes like pyrolysis, ChemCycling converts hard-to-recycle plastics into high-quality feedstocks, which can be reused to produce new plastics. This innovation is central to BASF’s vision of a circular economy, where plastics are recycled, reused, and reintegrated into production cycles, reducing waste and carbon emissions.

BASF’s ChemCycling garnered significant attention not only for its technical innovation but also for the strong partnerships it has forged. Several key companies joined the initiative to help scale the technology and integrate it into the broader recycling infrastructure:

- BASF & Pyrum Innovations: Closing the Loop on Plastic Waste

- BASF invested €16 million in Pyrum to expand its tire pyrolysis plant. This investment supports the processing of pyrolysis oil into chemical products, closing the loop for post-consumer waste and replacing fossil feedstocks in high-quality plastics.

- Henkel: Leading the Way with Chemically Recycled Packaging

- BASF worked with Henkel to explore the use of chemically recycled materials in consumer and industrial products. Henkel became the first company to produce bottles made entirely from chemically recycled plastic, underscoring its commitment to sustainability.

- Schneider Electric: Enhancing Product Performance with Recycled Materials

- BASF teamed up with Schneider Electric to develop miniature circuit breakers using chemically recycled Ultramid, advancing the circular economy without compromising product safety or performance.

- Quantafuel: Turning Mixed Plastic Waste into High-Quality Feedstocks

- BASF partnered with Quantafuel to further develop chemical recycling of mixed plastic waste into high-quality feedstock, offering an alternative to fossil resources.

- REMONDIS: Advancing Chemical Recycling for a Sustainable Future

- BASF and REMONDIS collaborated to enhance chemical recycling solutions, turning plastic waste into premium raw materials for BASF’s ChemCycling initiative, driving forward the circular economy.

These collaborations demonstrate the growing industry commitment to solving plastic waste challenges and supporting the transition to a more sustainable, circular plastics economy. BASF’s ChemCycling is a promising step forward, making plastic recycling more efficient, scalable, and environmentally friendly.

Fusing Innovation with Sustainability

At the intersection of innovation and sustainability, Sentient By Elysian stands as a transformative force, empowering brands to spotlight their eco-conscious breakthroughs. With a keen understanding of AI-driven technologies and experiential marketing, Sentient helps companies bring their vision for a greener future to life—whether in design, engineering, or product development. Their work champions the principles of reducing carbon footprints and fostering a circular economy. Through collaborative partnerships with industry leaders, Sentient showcases how innovative technologies can not only drive sustainability but also minimize environmental impact across a spectrum of industries.

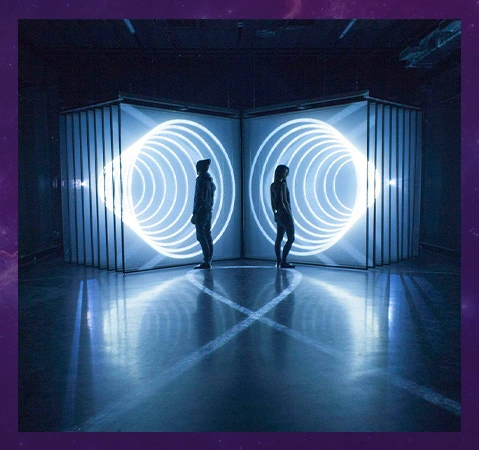

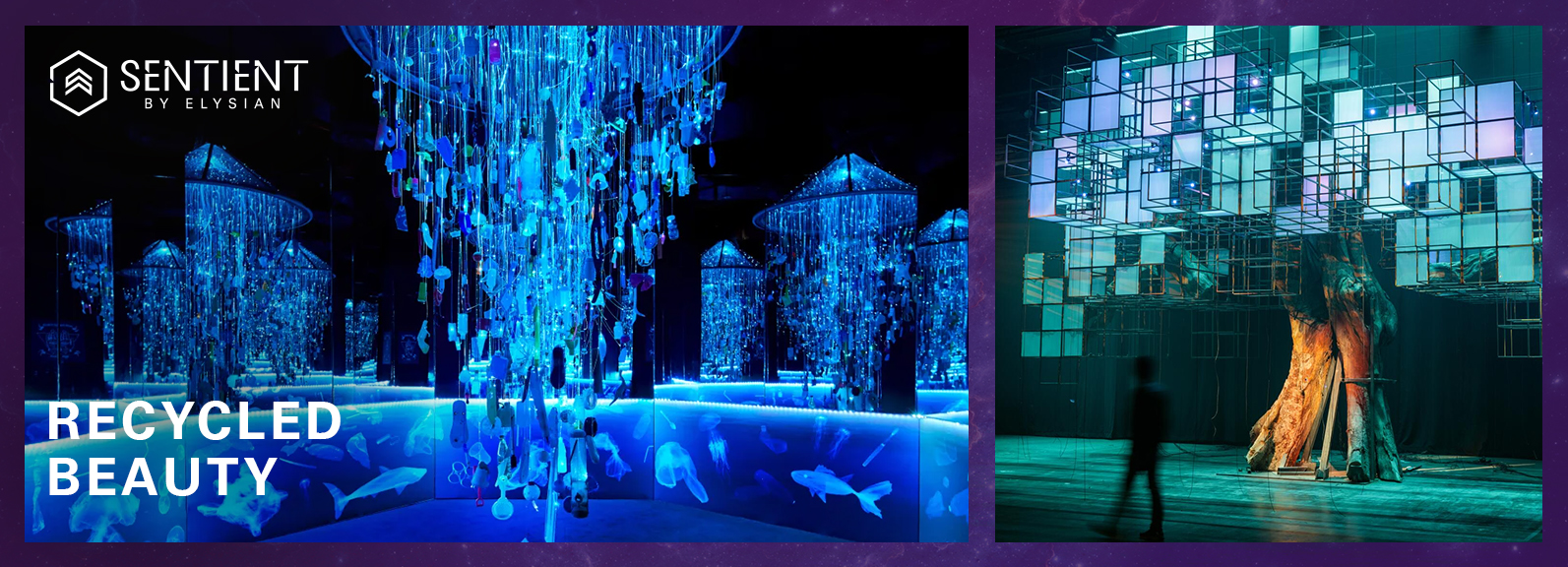

A standout example of Sentient’s commitment to sustainability is their immersive Escape Room experience, where sustainability is at the heart of the challenge. Players are transported into a world where every puzzle revolves around environmental responsibility—solving problems that address waste reduction, energy conservation, and sustainable resource management. As they advance through the game, participants are not only engaged in critical thinking but also gain valuable knowledge on sustainable practices that can be applied in real life. By merging fun and education, this concept highlights how sustainability can be both a dynamic experience and a powerful tool for change, inspiring players to incorporate greener choices into their daily routines.

VisionVenture: Shaping the Future of Travel with BASF's Cutting-Edge Technology

At K 2019, the VisionVenture stole the show, showcasing BASF's dedication to revolutionizing travel through sustainable material innovation. Created in collaboration with HYMER, this visionary camper van redefines mobility with cutting-edge design, performance, and eco-conscious solutions. It integrates over 20 of BASF's high-performance materials, from lightweight plastics to advanced coatings, highlighting breakthroughs in energy efficiency and comfort for both automotive and travel industries.

The VisionVenture blends natural materials like hemp and slate with BASF’s innovative plastics, offering a sleek, sustainable design. Key innovations include the Elastollan-coated, self-inflating pop-top roof for superior water resistance, and Elastocoat C Spray Gel that keeps mattresses fresh. A standout feature, Veneo Slate, combines natural stone with lightweight plastic, providing a flexible, stylish interior surface. Additionally, the van incorporates SLENTEX and SLENTITE insulating materials for enhanced thermal protection, while BASF’s Ultramid polyamides ensure durability in critical components. Chromacool paint and Infinergy polyurethane further elevate its eco-friendly performance, proving that sustainable materials can drive both comfort and performance.

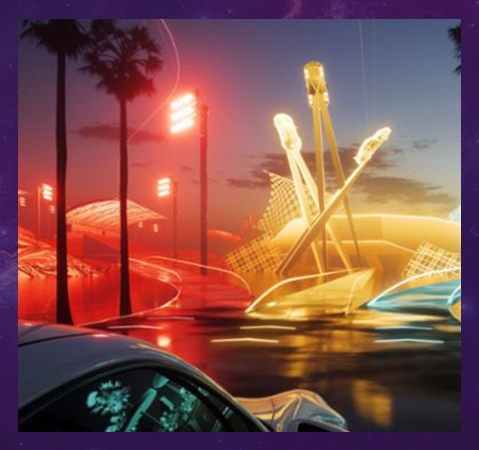

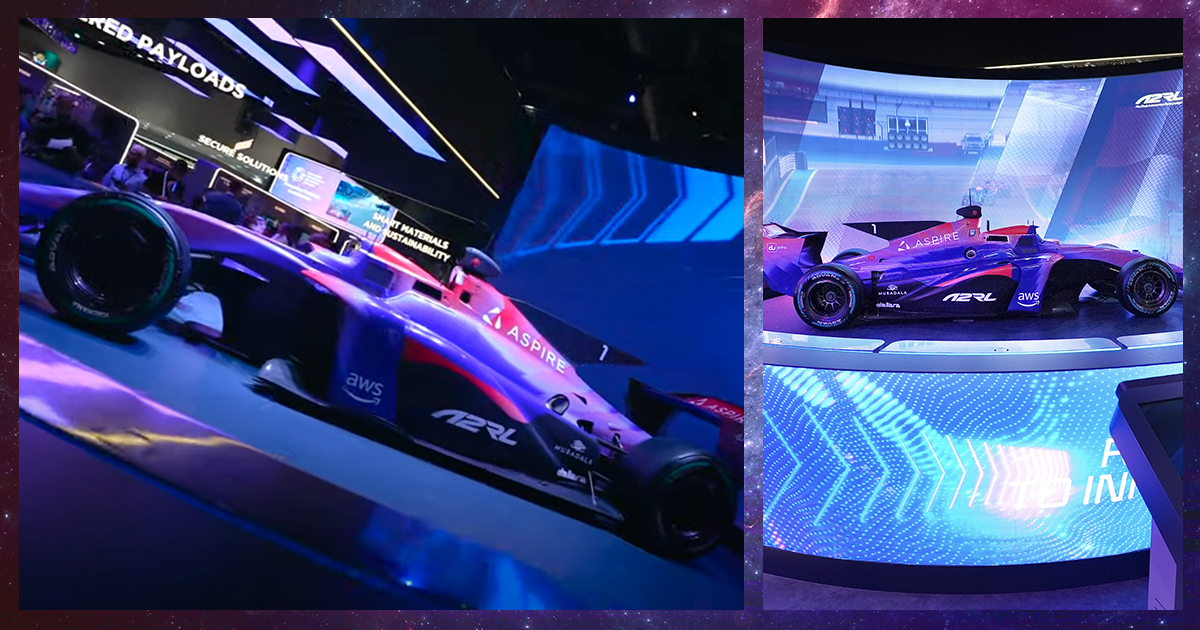

Revolutionizing Automotive Reveals with Sentient By Elysian's Peek-A-Boo

On a similar note, Sentient By Elysian's Peek-A-Boo is transforming how global audiences experience automotive reveals. This 4.5-meter spinning display, with over a million LEDs, combines 4K curved screens and surrounding panels to create an immersive, dynamic narrative. Whether unveiling products or launching major campaigns, Peek-A-Boo engages the senses, offering unparalleled storytelling possibilities.

At GITEX Global 2024, the Dallara EAV24 autonomous race car was revealed using this groundbreaking technology, captivating audiences with a futuristic spectacle. Peek-A-Boo is more than just a display—it’s a fully integrated platform that brings brands to life in unforgettable ways, merging technology and creativity to leave a lasting impact.

Much like the groundbreaking material innovations seen in BASF’s VisionVenture, Peek-A-Boo transcends the role of a mere display. It serves as a dynamic, all-encompassing platform that transforms storytelling into an immersive experience on a global scale. Through a seamless fusion of cutting-edge technology and imaginative design, Sentient by Elysian’s Peek-A-Boo breathes life into a brand’s narrative, captivating audiences and leaving a lasting, inspiring impression across the world.

To Wrap It Up!

BASF and Sentient by Elysian are shining examples of how innovation and sustainability go hand in hand. At K 2019, BASF introduced the VisionVenture, a sustainable camper van made with over 20 advanced materials that reduce carbon footprints while boosting performance. With eco-friendly plastics, natural stone composites, and energy-efficient solutions, BASF is paving the way for a greener future in the automotive and travel industries.

Sentient by Elysian, on the other hand, is revolutionizing experiential marketing with Peek-A-Boo. By weaving sustainability into interactive experiences, they’re creating lasting moments that inspire eco-conscious behavior. Their blend of technology and sustainability encourages brands and audiences alike to make more sustainable choices.

Together, BASF and Sentient by Elysian prove that innovation can drive progress while protecting the planet, showing the power of sustainable solutions for a better, greener world.

Website | LinkedIn | Instagram | YouTube | Facebook