Understanding Mechatronics Integration Services: A Comprehensive Guide

share

Summary

The article explores mechatronics integration as the fusion of mechanics, electronics, and software to build intelligent machines that reshape industries. It explains how integration services bring together hardware, software, and creative design to create systems that go beyond function—acting as both tools and artistic experiences. From prototyping and hardware design to real-time content synchronization, mechatronics drives innovation, efficiency, and immersive interaction. The importance of integration lies in enhanced performance, cost reduction, and cross-disciplinary innovation. Sentient By Elysian is highlighted as a pioneer in leveraging mechatronics for healthcare simulations, merging engineering precision with creativity to transform medical training and brand experiences alike.

Table of Contents

Introduction to Mechatronics Integration

What Exactly is Mechatronics Integration?

Why is Mechatronics Integration Important?

The world is swiftly progressing towards a future defined by automation and interconnectedness. Technology is integrating mechanics, electronics, and computer science to create a seamless fusion of self-driving vehicles and tireless robots that are transforming the manufacturing industry. The combination of mechanical engineering and electronics is referred to as mechatronics, and the processes involved in making it functional are called mechatronics integration services.

This integration encompasses more than simply the most recent technological devices; it is at the core of a significant revolution in the industrial environment. However, what precisely does mechatronics integration entail? Let us further explore and examine the possibilities of this revolutionary technology.

What Exactly is Mechatronics Integration?

Imagine a world where machines seamlessly collaborate, blurring the lines between mechanics, electronics, and software. This is not science fiction; it is the seamless and coordinated reality created by mechatronics integration.

Mechatronics integration services take this idea a step further. These services cover the complete process of designing, developing, and deploying integrated systems. Consider it as a conductor conducting a symphony, ensuring that each instrument (mechanical components, electronic sensors, and software programs) performs its role perfectly. What was the result? Machines can collect data about their surroundings via sophisticated sensors, evaluate that data using powerful computers, make real-time choices, and take actions based on those conclusions, employing actuators such as motors or manipulators.

Essentially, mechatronics integration spans the physical and digital worlds. From the mind-blowing accuracy of self-driving automobiles to the awe-inspiring agility of robotic limbs, mechatronics is already changing the world. But let's go deeper and learn about the essential characters in this mechanical masterpiece.

Inside the Machine: A Closer Look at Its Structure

Mechatronics integration is the process of bringing together many technical disciplines to achieve this harmony. The design process in mechatronics consists of multiple detailed processes, ranging from original idea and material selection to component integration, software analysis, and final testing. It requires not only a thorough grasp of various technical concepts but also ingenuity and problem-solving abilities to push the frontiers of automation and technological innovation.

Here's a deeper look at the main steps involved:

- Advanced Prototyping: The stage uses rigorous design methods, including 3D printing, to produce both functional and visually attractive assembly components. Furthermore, material selection is crucial, with options ranging from flexible plastics to robust metals that have all been tuned for performance, strength, and aesthetic appeal. In addition, feasibility tests, load analysis, and virtual simulations are performed to provide a holistic approach to engineering design. This protects the structural integrity and safety of the system.

- Precision in Hardware Architecture: Creating a strong hardware design is critical for providing accurate feedback and ensuring dependable operation under changing situations. When working with complicated kinetic systems, choosing the appropriate motors, actuators with integrated encoders, and PID controllers is critical. These components are carefully selected based on certain performance characteristics, such as torque, speed control, power consumption, payload capacity, and others, to ensure maximum functionality and efficiency.

- Detailed Electronic Design: Wiring and PCB design need precise electronic calculations and datasheet analysis. Protoboards are used for schematic design and early testing of PCBs, ICs, and other electronic components before they are moved to industrial-grade PLCs, enabling simplified maintenance and control.

- Microcontroller-Based Hardware Programming: Microcontrollers are essential for integrating a wide range of electronic devices since they can perform a variety of functions such as reading sensor inputs, regulating motors, operating displays, switches, relays, actuators, and more. They accept input data from numerous devices, process it, and control output via communication interfaces such as UART, SPI, I2C, Bluetooth, and WiFi, enabling complicated integrations with a variety of IoT projects and applications.

- Integration with Software Platforms: TouchDesigner and game engines are used to improve communication and combine advanced UI/UX front-end interfaces, hence improving user interaction and visual design. For responsive interactions with the hardware backend, communication protocols such as Serial and Osc are employed, followed by network-based communication via UDP, TCP, and Websockets.

- Enhanced Interaction with Real-Time and Playback Artistic Content: The synchronization of a wide range of file types for both real-time and pre-recorded information using industry-standard software tools and plug-ins offers flexible and complete content management. Advanced media integration accomplished using in-house built specialized slice engines uses exact pixel computations to allow for the stacking and mixing of various media kinds, lighting, and fine-pitch LED displays, resulting in a rich, sensual multimedia experience.

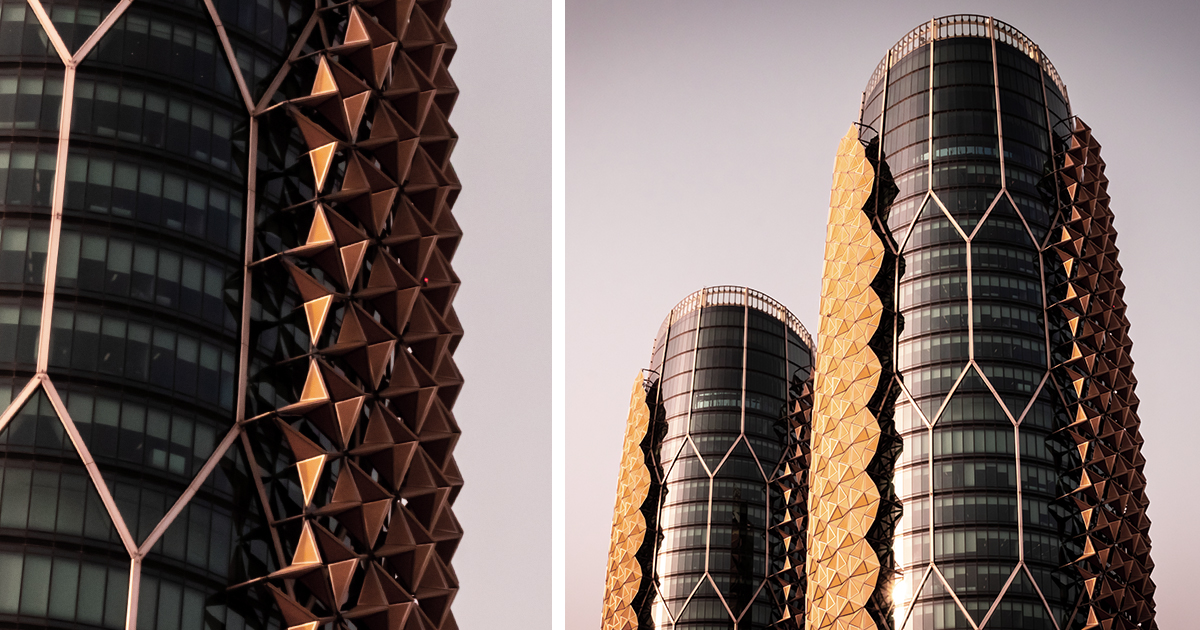

The combination of engineering and creativity is what distinguishes mechatronics; these systems often combine sophisticated robotics, precise hardware integration, and creative programming. These installations are not only practical; they also serve as brand ambassadors and works of art. These systems convert passive observation into active participation by using cutting-edge technology such as real-time motion tracking, responsive actuators, kinetic mechanisms, and interactive digital interfaces. This not only catches people's imaginations but also builds a long-term, creative relationship with the brand across several sectors.

Why is Mechatronics Integration Important?

The value of mechatronics integration originates from the remarkable synergy it generates by combining multiple technical disciplines. Here's a summary of some major benefits:

- Enhanced Functionality: Mechatronics integration is the combination of mechanics, electronics, and software to build intelligent machines capable of performing complex tasks and adapting to changing environments. Consider a robotic arm at a factory that can not only move things but also vary its grip strength depending on the material being handled.

- Improved Performance: Optimized designs that include several features lead to machines that are quicker, more accurate, and more dependable. Self-driving automobiles, for example, use mechatronics to accurately regulate steering, braking, and acceleration, resulting in smoother and safer rides.

- Reduced Costs: Combining features might result in a lower physical footprint for a system and more efficient manufacturing processes. This results in cost reductions for materials, labor, and total system complexity.

- Greater Innovation: Mechatronics integration facilitates collaboration among engineers from many fields. This cross-pollination of ideas produces innovative solutions and pushes the limits of what is possible. Consider medical gadgets that combine precise mechanics with real-time data processing, resulting in transformative advances in healthcare.

Sentient By Elysian: Elevating Brands with Mechatronics Expertise

Sentient By Elysian, a leading experiential and immersive technology business, uses mechatronics integration to design custom mechatronic systems for realistic medical simulation. These systems simulate physiological processes and surgical operations, giving healthcare practitioners a realistic environment to enhance their abilities. The systems include haptic feedback systems, which enable surgeons to perform delicate operations with accuracy.

Furthermore, they can be built to imitate a variety of medical crises, allowing trainees to practice critical thinking and adaptation under duress. The integrated software analyzes vital signs and performance indicators. This allows for real-time data analysis. This input is useful to both trainees and instructors. These mechatronic simulation systems provide a novel training experience for healthcare workers, shaping the future of medical education and, ultimately, improving patient care.

Bottom Line

As technology evolves, mechatronics integration continues to play an important role in determining the future. We should expect to see progressively more intelligent and adaptive robots that interact seamlessly with their surroundings, transforming many parts of our lives.

Mechatronics integration services drive the development of intelligent machines. From increasing efficiency to encouraging creativity, these services are reshaping industries and defining the future of technology.

If you want to use mechatronics to transform your production processes, look no further than Sentient By Elysian. The company's skilled staff is devoted to assisting you in developing tailored solutions that not only increase efficiency and quality but also move your organization into the future of intelligent manufacturing.

Contact Sentient By Elysian now to learn how mechatronics integration may transform your path in your business.

Website | LinkedIn | Instagram | YouTube | Facebook